The Solar Stirling Engine from Infinia Corporation

Jim Clyde was interviewed by Robert Pritchett for this

article

“Originally developed

by Robert Stirling in 1816, the Stirling cycle uses a working fluid (typically

Helium, Nitrogen or Hydrogen gas) in a closed cylinder containing a piston.

Heated on one end and cooled on the other, the expansion and cooling of the gas

drives the piston back and forth in the cylinder. The work performed by this

piston-motion is used to drive a generator (in Infinia’s case, a patented

linear alternator) or to create pressure waves to drive a compression process.

The cycle can be

operated in reverse by using the generator as a motor to drive the piston. In

this case, the continuous expansion and cooling of the working fluid caused by

the piston motion creates a cooling effect. These types of systems are called

Stirling coolers (also referred to as cryocoolers) and can maintain

temperatures as low as 10 Kelvin

(-263°C, and –442 °F).”

I remember

this company back in the 1980’s (three company name changes ago) when it was

working on the engine vehicle. When I asked about it, I was told it

was before Jim Clyde’s time at Infinia and so that was buried deep in the past.

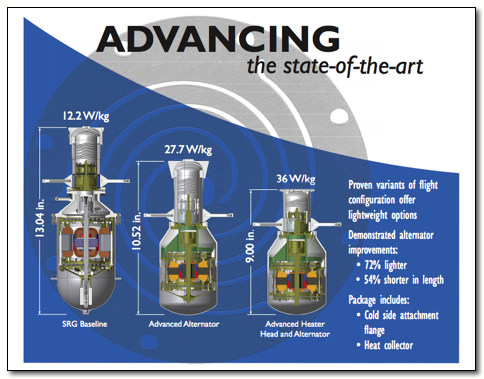

Infinia Corporation worked with NASA back then

to get a nuclear-based power plant on to a space probe to Mars that could

withstand being bottle-rocketed into space from earth, survive the landing on

Mars and do its job for 17 years without failing.

Based on those successes in space, they moved on to using

this maintenance-free, free-piston generator system for ground-based

mission-critical applications for the military and other government

organizations.

Remember the program on TV with Tactical to Practical? More

Perhaps Infinia was the inspiration for those episodes by

showing how tax-based projects can be converted into real public good.

Today the little engine that could can be found in

rare-to-be-found-publicly portable generators, vehicle auxiliary units and mini

combined heat and power (CHP) systems. But that is about to all change soon.

Infinia received some well-deserved venture capital to take

it up a notch from Paul Allen’s Vulcan Group. They are being extremely

conservative about what is possible and what has been accomplished so far and

that is probably why you never heard of them before. But you will. I’ll see to

it.

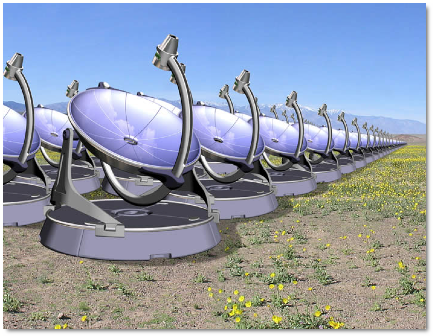

Why? Because they are also using this inspired device to

generate electrical power from sunlight!

Will you be able to have this on your roof? No. At least not

in the near future.

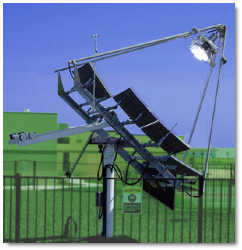

Will you be able to have this on the ground using a 2-axis

stand (2 axis poles provide 50% increase in efficiency)? Yes – if you are

a commercial site.

Will there be

direct sales or dealerships? Yes, to fill government contracts. Yes, to solar

distributors for commercial installations. Will there be

direct sales or dealerships? Yes, to fill government contracts. Yes, to solar

distributors for commercial installations.

How soon? The Solar collector and engine units will

be visible at the company location in October with prototypes being tested

around the USA in January, so expect (if nothing goes wrong) these units to be

available in the Fall of 2008. They just removed the “1st gen” that

was located just west of their building that had been there for nearly 2 years.

I thought it was a closed-circuit broadcast dish that the local TV stations

use. Boy, was I wrong!

The $2-billion + alternative energy industry is heating up

and you will have to wait in line after the government and commercial entities

have gorged at the feeding trough first. Perhaps by then the whole unit will

have been reduced in size even further. Can you hold out for the roof-top

version in 2 or more years (if ever)?

This is tantalizing tech!

The key to all this effort are the patents that have been

carefully and patiently preserved for close to 2 decades.

|

|

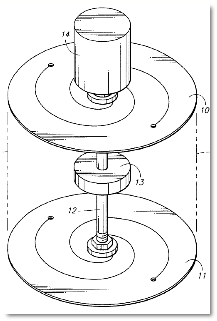

Conceptual

Design |

Closer to

Reality |

And what I feel is the real key to the free-piston engine is

the patented flex-spring technology shown above. You wouldn’t know it by just

looking at it, but if you pushed down on the handle in the first picture, the

two “wheels” would flex downward (assuming the outer edges were anchored to

something) and in the 2nd picture, the holes in the outer rim are

for anchoring. The center would be where the free-piston would be located and

there are 6 or eight of these rings that can flex a few millimeters in either

direction as the gas heats and cools inside the hermetically sealed engine.

The recent job postings at Infinia indicate that this

technology is going to leap Photovoltaics in the next year or so, because it

can do nearly twice the power in the 1/3rd the space and for less

cost than for a Photovoltaic array based on the same power requirements. Fewer

parts, cleaner design, smaller components equals quick assembly (relatively

speaking) in comparison to the turn-around time for photovoltaic cells to

finally get to sunlight and produce power.

Internally these electric-generation jewels contain not only

the generator, but the alternator and the inverter, none of which have

mechanically moving parts. No brushes, no bearings to wear out, etc. What was

simple has been made even simpler still.

The materials are essentially off-the-shelf metal parts that

do not have the legacy issues of pollution and brown-fielding activities

associated with the long process of creating silicon-based solar cells. (By the

way, one of the largest manufacturing facilities for solar silicon is also here

in Washington State – except all product is being shipped to Norway for

further processing and used in Europe. So far, none of it has “reached home”.)

The latest 3.3kW stirling engine unit is going the solar

mirror dish route and those units take up a little bit of space. In this

picture below, think of the frame as a gun turret for side-to-side and swivel

up-and-down motion.

Remember the first set of dishes that came out for satellite

reception? These are smaller. A real live one will be planted next to the

Infinia Corporation building in Kennewick, WA soon, so concept will become

reality.

Why did I interview Jim Clyde (VP of Marketing and Business

Development) now instead of waiting a year? Because it would be really sweet if

I could have a day job with a company that has taken “old” technology, spiffed

it up and made it leapfrog what we would consider the latest in Solar Tech

today. And because I wanted to see for myself if this technology was

consumer-ready for prime-time. Just hold your breath for a little while longer…

Meanwhile, the engine by Infinia Corp is seeing the

light of day in systems being OEMed to Rinnai in Japan for combined heat and

power units that probably will be sold here in the US within a year and also by

Enatec in the Netherlands.

|

|

Rinnai |

Enatec |

What was old has been made new again and we can see that the

“not invented here” syndrome does not exist at this company. They have taken

the best of the best and made it literally shine around the world!

A presentation was given to the Alternative Energy User Group January 4th, 2008 by Seth Poulson and Rocco Luongo.

|